Explosion Safety

Pol-Safety Veiligheidsadviseurs B.V. specialises in ATEX issues. Because of our chemical background and expertise in both occupational health and safety, we are able to make well-founded risk assessments.

The expertise lies mainly in the area of establishing ATEX zones and the control and reduction of Atex zones. These are questions that come up both in the design process of new installations and in drawing up explosion safety documents.

Below you will find more information per subject about the services we can offer.

What means ATEX?

ATEX

ATEX is an abbreviation from the European regulations and stands for ATmospheres EXplosibles. It is a reference to the European legislation that deals with the management of explosion risks under atmospheric conditions. At European level there are 2 directives that are relevant in this context:

- ATEX Directive 1992/99/EC (better known as ATEX 153 Directive), which describes the minimum safety requirements for employers to create a healthy and safe working environment for employees who may be at risk from explosive atmospheres. In the Netherlands, this directive is included in the Working Conditions Act.

- ATEX Directive 2014/34/EU (better known as the ATEX 114 Directive), which describes the requirements for equipment (both electrical and non-electrical) and protective systems intended for use in places (“zones”) where dust or gas explosion hazards may occur. In the Netherlands, this directive is included in the Warenwet.

The numbers 153 and 114 are numbers that refer to the chapters in the European Treaty of Lisbon and have no other specific meaning.

How is an explosion created?

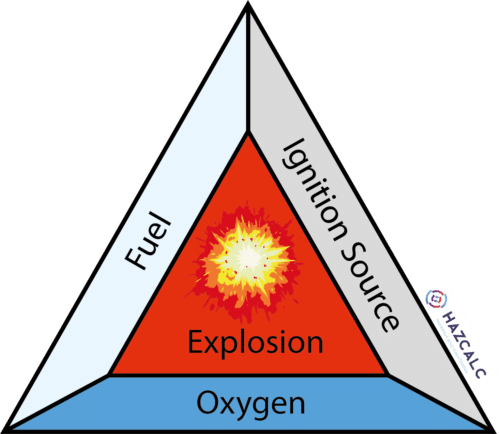

ExplosionsExplosions can be caused by various things: there are chemical explosions, explosions caused by unstable substances and physical explosions. However, the ATEX regulations focus on explosive atmospheres which can be caused by both flammable gases and liquids and flammable solids. The latter category does not include unstable solids but combustible (mostly organic) solids. An explosive atmosphere is defined as a mixture of flammable gas or dust with air, which after ignition, is inherently flammable.

An explosion can occur if a minimum quantity of flammable substance is present, combined with the right amount of oxygen in the presence of an ignition source. This is shown in the above ignition triangle. A rapid self-ignition will then occur. During this ignition, a great deal of heat is released and a significant increase in volume takes place. The rapid volume increase creates a shock wave which, in addition to the heat and fire load, can cause a great deal of damage. |

What means ATEX 153?

ATEX 153

ATEX 153 is a reference to Chapter/Article 153 of the European Treaty of Lisbon. This chapter lists the minimum requirements employers in the European Union must meet to protect employees from the risk of explosion.

The ATEX 153 directive is therefore a typical social directive, in contrast to the ATEX 114 directive, which is a typical product directive.

What means ATEX 114?

ATEX 114

ATEX 114 is a reference to chapter/article 114 of the European Treaty of Lisbon. This chapter lists the minimum essential health and safety requirements with which equipment and protective systems suitable for use in potentially explosive atmospheres must comply.

The application of this directive is part of the CE marking on products marketed within the European Economic Area. The directive is applicable if 2 conditions are met:

- the equipment is used in areas where explosive atmospheres may occur, and;

- the equipment has its own potential ignition source.

What are ATEX zones?

ATEX zones

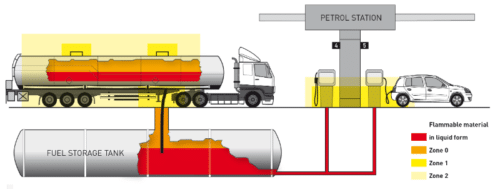

ATEX zones are areas at companies where explosive atmospheres may occur. These can be areas on the inside of installations, as well as areas in the present (working) areas and around installations in the open air.

There are various ATEX zones, in which a distinction is made for zones with flammable liquids/gases and for zones with flammable solids. The following zone areas are distinguished:

Types of zones:

| Zone 0 (gas)

Zone 20 (dust) |

place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour, mist or dust is present continuously or for long periods or repeatedly |

| Zone 1 (gas)

Zone 21 (dust) |

place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour, mist or dust is likely to occur in normal operation occasionally |

| Zone 2 (gas)

Zone 22 (dust) |

a place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour, mist or dust is not likely to occur in normal operation but, if it does occur, will persist for a short period only |

Examples of hazardous zones are :

| Examples of possible Atex zones in the interior of installation parts are: | Examples of possible Atex zones in (work) areas and/or around installation parts are: |

|

|

What are the requirements for ATEX areas?

Requirements for hazardous areas

As soon as danger zones are classified, special requirements apply. These requirements can be divided into

- technical requirements relating to the equipment to be used;

- organisational requirements for safe work by employees and third parties.

Equipment Requirements

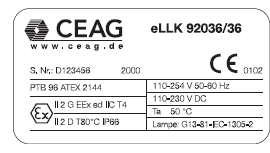

Equipment which must be used in hazardous areas must comply to the Regulations of the ATEX 114 Directive (2004/34/EU):

- In a zone 0 or 20: only category 1 equipment permitted, i.e. in the event of a double fault or foreseeable fault this equipment must not be a source of ignition;

- In a zone zone 1 or 21: only category 2 equipment permitted, i.e. in the event of a single fault or a foreseeable fault this equipment shall not be a source of ignition;

- In a zone 2 or 22: only category 3 equipment permitted, i.e. during normal operation such equipment shall not be a source of ignition.

In addition to the correct selection of equipment in hazardous areas, it must of course be ensured that the equipment continues to work correctly during its service life and may not be a source of ignition. This can be caused by wear and tear, damage or incorrect installation. This must be ensured by means of periodic inspections.

Summary

In summary, this means that, depending on the danger zone, equipment may not be a source of ignition. In principle, equipment should be Atex certified according to the ATEX 114 directive. If this is not the case, the explosion protection document must show whether additional requirements apply to the equipment being used. The latter is unlikely to be the case, unless it appears that the equipment in question does not have its own potential ignition source and can therefore be used safely in the hazardous area. An example is a manually operated valve.

The following applies to all electrical equipment: explosion-proof design (read: certified on the basis of the ATEX 114 directive) according to the correct equipment category, gas/dust group and temperature class. For all non-electrical equipment applies: non-explosion proof certified equipment is only allowed if the equipment does not have its own inherent ignition source. An example of this is a manually operated valve or a very slowly rotating shaft sleeve.

Organisational requirements

Organisational requirements in hazardous areas are primarily aimed at ensuring that employees or third parties such as contractors do not introduce ignition sources into the hazardous areas. This must be ensured organisationally by:

- Marking out danger zones at workplaces with warning signs and/or markings;

- instructing employees about danger zones and the required working methods;

- setting requirements for work clothing and/or work footwear (e.g. anti-static);

- working with work permits;

- securing installation parts prior to maintenance activities;

- etc.

More Information

For more information about the possibilities of our commitment, please contact us. The easiest way is 06-33046460 or via e-mail.