PL/SIL

If machinery is to be or is to be fitted with safety control devices, these must meet certain reliability requirements. These reliability requirements depend on the size of the risk that the safety control has to protect against: the higher the risk, the higher the reliability of the safety control.

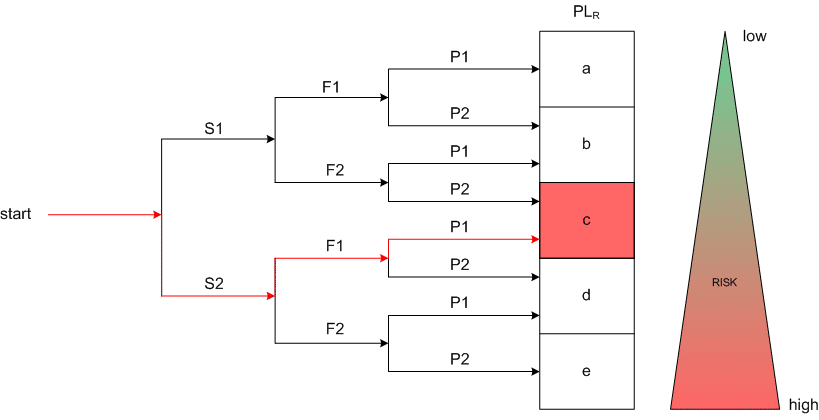

There are several standards that can be applied to determine the reliability level of electronic safety controllers. In mechanical engineering, the Performance Level based on NEN-EN-ISO 13849-1 is often applied.

The standard works in such a way that based on the severity of the risk, a Required Performance Level (PLr) is determined. Then, depending on the required reliability, a safety control system must be designed. The reliability of components (contactors, switches, relays) can be varied or redundant systems can be used. The actual performance level (PL) is then determined based on the chosen system structure, component reliability and the presence of fault detection. The system meets the requirements if the PL is greater than or equal to PLr.

Redundant systems are often required for protection against major risks, although NEN-EN ISO 13849-1 offers scope to achieve the second highest reliability level with single circuits.

Safety Integrity Level (SIL)

In the process industry and process installations, the Safety Integrity Level (SIL) based on NEN-EN IEC 62061 is often used. The SIL level, like the PL, also concerns the reliability of the safety control system. NEN-EN IEC 62061 applies exclusively to electronic safety controllers.

SIL verification

When designing safety controllers it is necessary to verify whether the designed safety controller achieves the required SIL class. This can be done by considering the individual components and determining their maximum achievable SIL class and by considering the chain architecture and determining the Predicted Failure on Demand (PFD) of the Safety Instrumented Function (SIF). The PFD of the SIF then shows whether the required SIL class can be achieved with the intended design.